-

Engineering Design

NEPEAN Longwall

Engineering Design

NEPEAN Longwall has been designing longwall equipment for the Australian market since the year 2000. In order to meet the requirements of new equipment and overhaul modifications, we have located designers and draftsmen where they can play a hands-on role and deal directly with the customer at each of our service centres.

A point of difference when dealing with NEPEAN Longwall is that your preferences will be at the core of the design process which allows the design to develop according to your needs. Back in early 2002, NEPEAN Longwall sold its first complete coal clearance system to West Wallsend Colliery. The design process incorporated many ideas that the mine had to improve their longwall and the style of partnership became a model for how NEPEAN Longwall would work with its customers.

In order to meet the extensive drawing requirements of large assemblies such as the longwall BSL, we involve drawing detailer teams from overseas to expand our capacity, improve lead times and allow our designers to focus on the product design.

As many of our key fabrications are made in China, we have placed draftsmen in China who can communicate with our suppliers and provide direct engineering assistance during projects. These personnel form a critical part of our engineering team and are pro-active in the development of the product and improved assembly design. They work directly with our suppliers, interpreting material selection and plate availability to streamline manufacturing processes.

DEM Modelling

- Transient particle flow analysis considering particle to particle and particle to wall interaction, internal/wall friction & energy loss

- Spherical and non-spherical particles (variable particle shape, density & size distribution)

- Particle cohesion & arching (sticky particles)

- Static, moving (translational/rotational) & vibrating boundaries

- Particle breakage

- Surface wear

- Fluid-solid particle interaction for packed/fluidised bed particle flow modelling

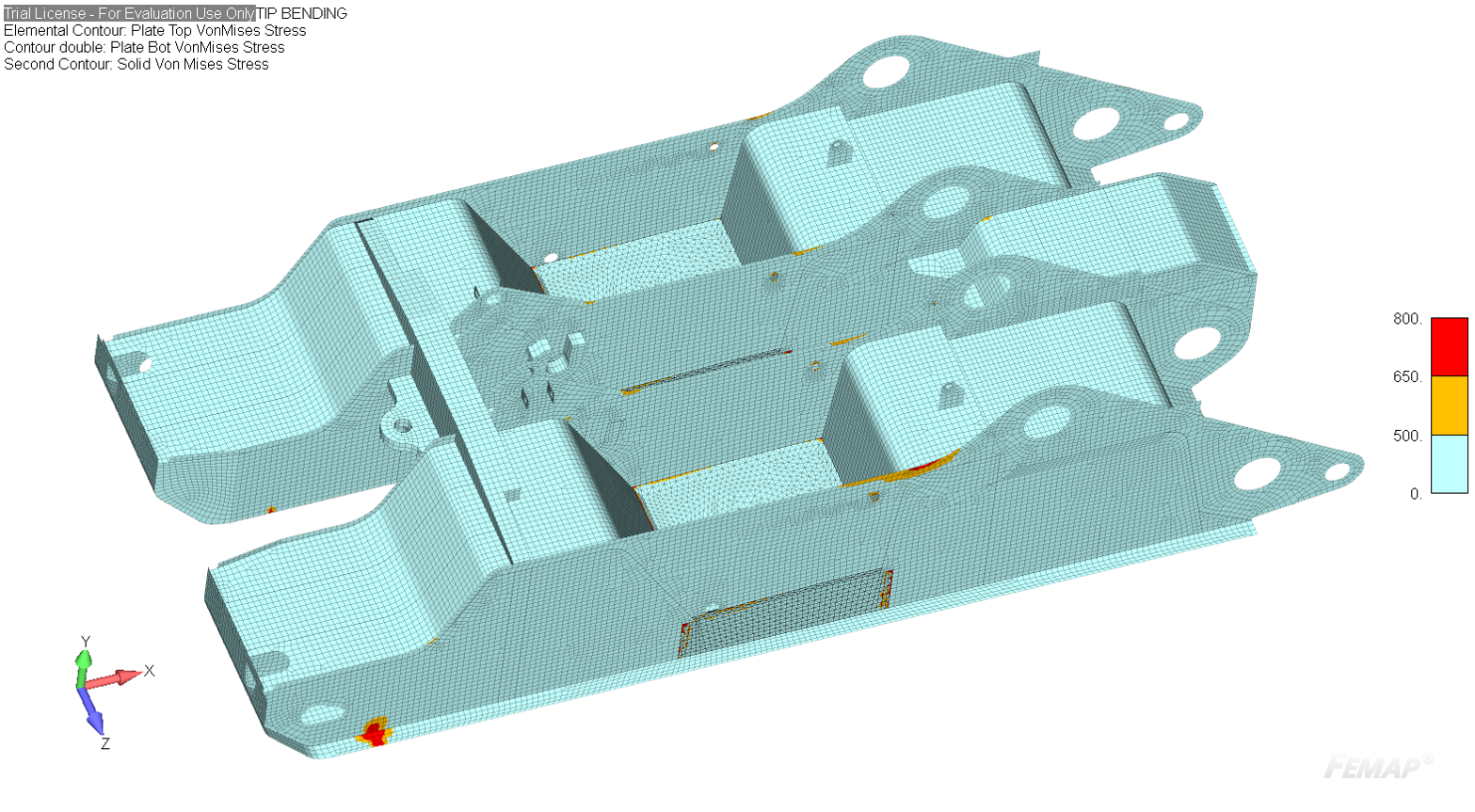

Structural Analysis

- Load cases assessed against design criteria

- Von-Mises stresses compared with allowable stress

- Static linear elastic analysis

- FEA and potential modifications assessed

- Assembly stiffness and load transfer

- Axial and shear loads of pins assessed

- Typically 16 or more load cases assessed on roof supports